Podcast: Play in new window | Download

Subscribe: Apple Podcasts | Email | TuneIn | RSS | More

In this post, we utilise Google’s LM Notebook to create a Deep Dive into this article.

Listen in to the deep dive and let me know what you think!!!

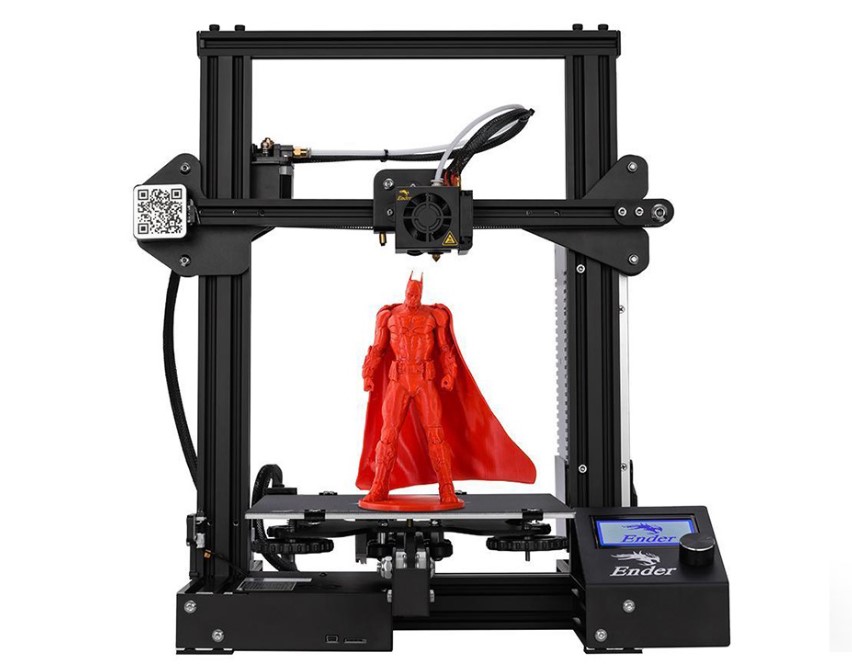

This article explores the surprisingly captivating experience of watching a 3D printer at work, delving into the perspectives of both the creator of a 3D model and casual observers. It questions whether this act is genuinely satisfying or simply hypnotic, examining the emotional, practical, and psychological elements at play.

Key Themes and Ideas:

- Dual Perspectives: Creator vs. Viewer:

- The Creator: For those who have designed a 3D model, the act of watching it print is a deeply personal and often emotional experience. It’s likened to watching a sculptor carve marble and it’s directly tied to their creative vision and anticipation of the final product.

- Quote: “For those of us who have spent hours—sometimes days—designing a model, watching it come to life can feel akin to witnessing a sculptor carving marble. The experience is deeply personal, tied to the creative process and the anticipation of seeing your vision materialise.”

- Practicality for Creators: Beyond the emotional aspect, watching a print can also provide invaluable insight into potential design flaws, allowing for refinement of the process. The creator can observe issues like poor filament flow or miscalculations.

- The Viewer: For those not involved in the design, watching a 3D printer can be a mesmerising experience due to the rhythmic movement of the print head and the slow transformation of filament into a physical object. This is often compared to watching a campfire – soothing and meditative.

- Quote: “For the uninitiated, the spectacle of a 3D printer at work can be downright mesmerising. There’s something hypnotic about the rhythmic movements of the print head, the hum of the stepper motors, and the slow but steady transformation of raw filament into a tangible object.”

- The Element of Satisfaction:

- Creator Satisfaction: For creators, satisfaction can stem from witnessing the culmination of their design efforts and from the troubleshooting and learning aspects of observing the print. It is also admitted that the novelty of watching a large print wear off and can become monotonous after a while.

- Viewer Satisfaction: Viewers find satisfaction in the precision of the printing process and the visual transformation, often condensed into time-lapse videos on platforms like YouTube and TikTok. The real-time experience is described as relaxing, if not always engaging for long periods.

- Quote: “These videos are undeniably satisfying, combining the visual appeal of precision engineering with the gratification of seeing a project completed in record time. But is the live experience equally captivating?”

- The Role of Time:

- Patience vs. Anticipation: Watching a print in real-time requires patience, and the article compares this to “watching a pot boil” where anticipation can sometimes outweigh the actual event.

- Time-lapse vs. Real-Time: Time-lapse videos significantly enhance the viewing experience for casual observers, condensing hours of printing into seconds or minutes, therefore providing an instant gratification. The live experience, while relaxing for some, might not hold the same level of engagement.

- Remote Monitoring and its Impact:

- Convenience: Remote monitoring via webcams or software like OctoPrint allows creators to oversee the printing process without being physically present. This is a practical benefit but potentially removes the immersive aspect of watching in-person.

- Enhanced Time-lapse: Modern printers often feature built-in cameras and time-lapse functions, and open-source tools like OctoPrint enhance the quality of time-lapse footage by homing the print head during capture. This also allows for cleaner and engaging footage to be shared.

- Connecting Creators and Viewers: Remote monitoring and live streaming open up opportunities to share the process with a wider audience, bridging the gap between creators and viewers.

- The Subjective Nature of the Experience:

- No Definitive Answer: Ultimately, the article concludes that whether watching a 3D print is satisfying or not is subjective. It depends on individual perspectives, personal interests, and the context of the print.

- Quote: “So, is watching a 3D print satisfying? The answer, unsurprisingly, is subjective. For creators, the process can be a blend of satisfaction, anticipation, and anxiety. For viewers, it’s often a mix of curiosity and relaxation, with the level of engagement varying based on personal interest.”

- A Shared Appreciation: The real value is perhaps found in the shared appreciation for the technology, whether you’re a maker looking for flaws, a viewer enjoying the process, or someone enjoying the condensed versions of the prints online.

Conclusion:

Watching 3D prints is a multi-faceted experience that engages different emotions and interests depending on whether you are a creator or a viewer. While creators find satisfaction in seeing their design come to life and spotting potential issues, viewers are captivated by the precision and mesmerising process. The use of time-lapses and remote monitoring adds another layer to how individuals experience the act of 3D printing. Ultimately the article concludes that appreciation for the process lies in the intersection of art and engineering and is down to the individual viewer.