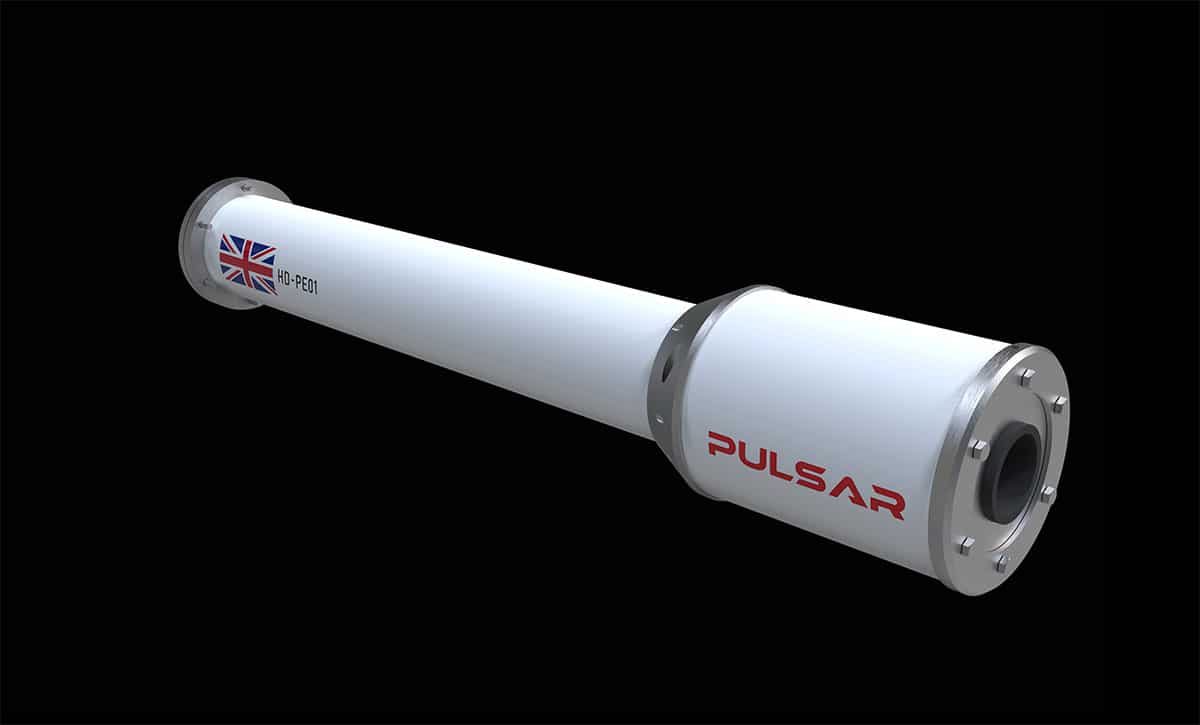

Pulsar Fusion Ltd, a UK nuclear fusion company based in Bletchley, has just developed and tested its first launch capable, high-power chemical rocket engine in the UK.

These rocket engines could be used for a variety of applications, including launching people and satellites into space.

The company’s ultimate ambition in the future is to produce a hyper-speed propulsion engine using nuclear fusion technologies for interplanetary travel – which scientists think could cut the journey time to Mars in half.

This successful set of test firings showcases the rapid design development and test process of high-performance engineering components to support Pulsar Fusion’s energy and propulsion hardware portfolio roadmap. The rocket engine proudly displayed the Union Jack flag during testing.

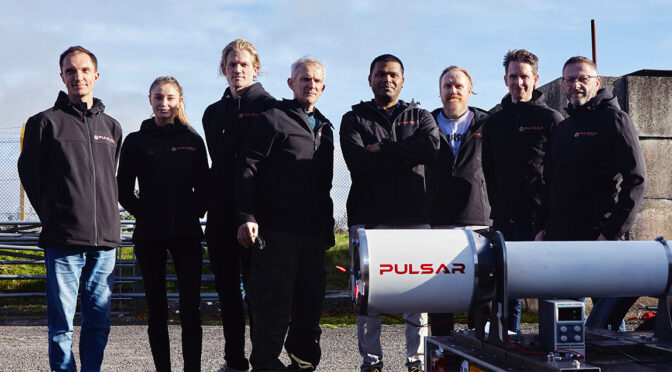

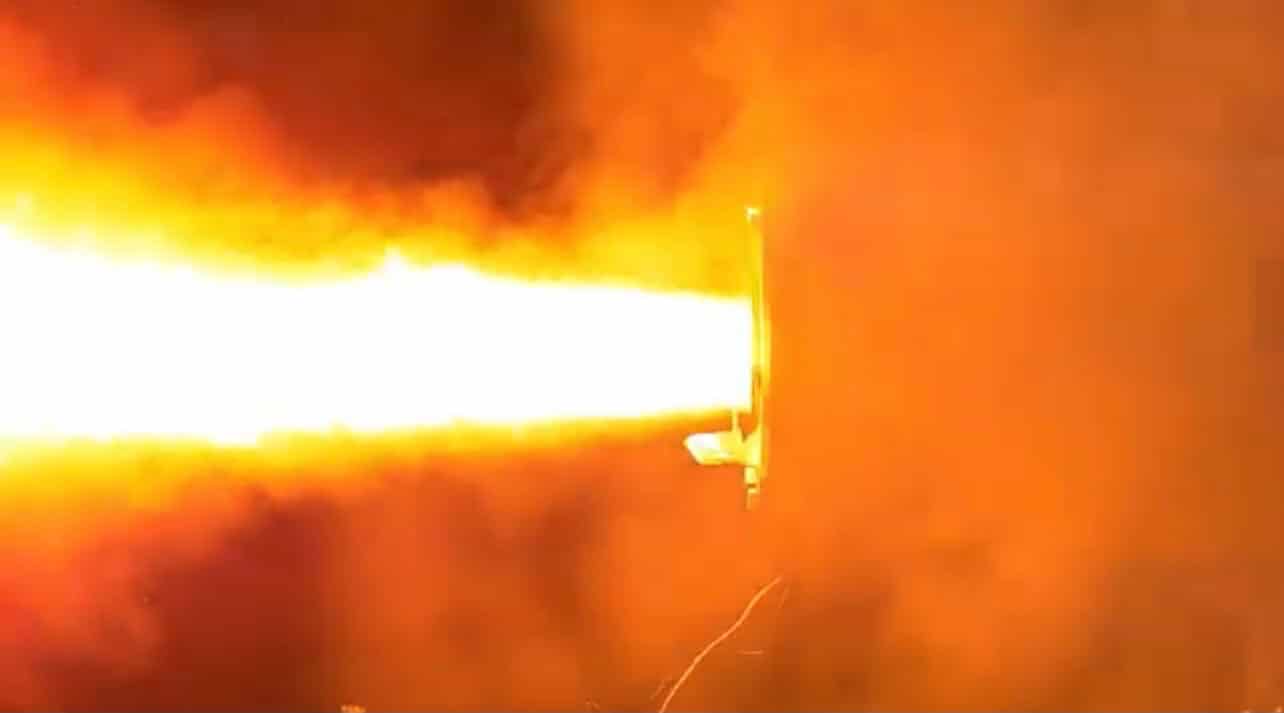

Pulsar’s UK acceptance tests at COTEC – Ministry of Defence military base in Salisbury, took place on November 17 and 18, 2021 (As pictured) which were static tests. These will be followed by an international demonstration for space clients in Switzerland on November 25.

This hybrid rocket engine has demonstrated impressive visual plume effects such as supersonic shock diamonds typical of a high temperature, high mass flow rate rocket exhaust.

CEO – Richard Dinan, commented: “We are delighted with the UK test firings at COTEC. It is a hugely significant moment and we are proud this rocket is built in the UK. To have a British rocket test on UK soil is novel.

“Pulsar is among a very few companies around the world to have built and tested these technologies. We have a team of fantastic scientists with a wealth of experience to thank for these milestones. We have also drawn talent from some of the UK’s top universities who have begun working with and testing our plasma thrusters at campus facilities. We are extremely proud of these achievements and look forward to expanding our network with the British and European space community with our hardware demonstration later this month in Switzerland.”

Pulsar’s ‘green’ (non-toxic) hybrid rocket engine combusts nitrous oxide (N2O) oxidiser and high-density polyethylene (HDPE) fuel and oxygen. It is a new model that enables Pulsar to manufacture these compact rocket engines at record lead times, with an enhanced safety factor as due to the design, these engines have relatively benign failure modes in comparison with conventional liquid propulsion engines.

A hybrid rocket engine has the following main components and requires control of only one fluid – a liquid oxidiser during testing. Liquid oxidiser is fed under a regulated pressure through a control valve into a combustion chamber containing a technology as proprietary.

Pulsar Fusion received UK government funding in September 2021 to further develop its HET (Hall Effect Thruster) plasma satellite engines, capable of 20 km / second particle exhaust speeds. These Pulsar thrusters have recently been tested at Harwell’s facilities where they withstood 20g’s of vibration, simulating a rocket launch. Pulsar now seeks to IOD test these engines. (In Orbit Demonstration).

The vision:

The company’s ultimate milestone is to produce a hyper-speed propulsion engine using nuclear fusion technologies of which it has been researching for nine years which could eventually be used for interplanetary travel – and which scientists say could halve the journey time from Earth to Mars. A first prototype is expected in 2025.

About the company:

Pulsar Fusion is an advanced propulsion technologies company. It manufactures compact and efficient satellite engines for use in orbit, and liquid rocket engines for launch and atmospheric propulsion.

By 2025 – the company wants to develop nuclear fusion propulsion engines for static demonstration.

By 2027 – the company wants to manufacture a nuclear fusion rocket engine to be launched and tested in orbit.

Pulsar’s fusion propulsion systems are enabled by the technology generated in the rocket engine programme.